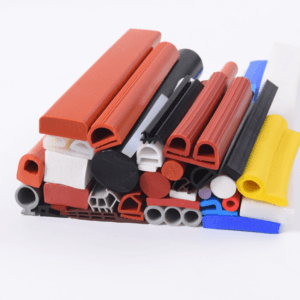

1. Foamed silicone, also known as additive silicone, is composed of silicone and curing agent in a 1:1 ratio. It is a white vulcanized material that becomes a soft elastic material

2. Foam silicone can be used for a long time and maintain its soft and elastic properties within a temperature range of -65 ℃ to 200 ℃. It is environmentally friendly and non-toxic, and has passed SGS environmental non-toxic certification.

3. Foamed silicone strips have excellent electrical properties and chemical stability, water resistance, ozone resistance, weather aging resistance, non corrosiveness, physiological inertness, non toxicity and odorlessness, low linear shrinkage rate, and easy operation

4. Foam sealing strips are usually lightweight, soft, and have good compressibility. The independent pore structure gives them good sealing performance, making them suitable for situations that require buffering and sealing.

Description

Silicone rubber foam silicone is a new type of polymer elastic material with excellent properties such as high-temperature deformation resistance and aging resistance.

Foam silicone strips have a long service life, can withstand high temperatures of 180 ° -220 ° C, and high-quality ones can reach 300 ° -350 ° C, with a Shore hardness of 25-35A.

Reviews

There are no reviews yet.